Strengths of Custom Manufacturing

Our nozzles are fully order made.

If using ready‐made nozzles from our catalogs, minor trouble may occur depending on the operating environment, application, or equipment.

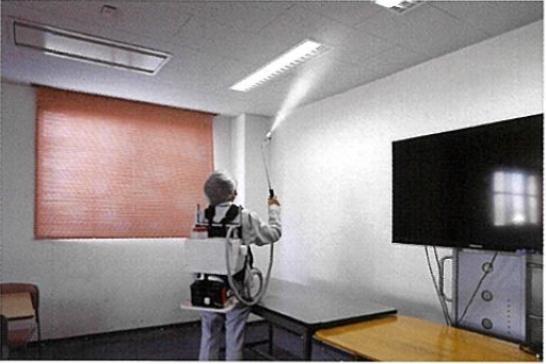

With fully order made nozzles, we can design and manufacture nozzles tailored to our customers’ applications, problems, desired benefits, operating environment, and equipment status.We offer a comprehensive solution up to providing customers with evaluation and testing data, and helping our customers optimize nozzle adoption, resolve problems, and get the most from our nozzles.

Evaluation & Testing

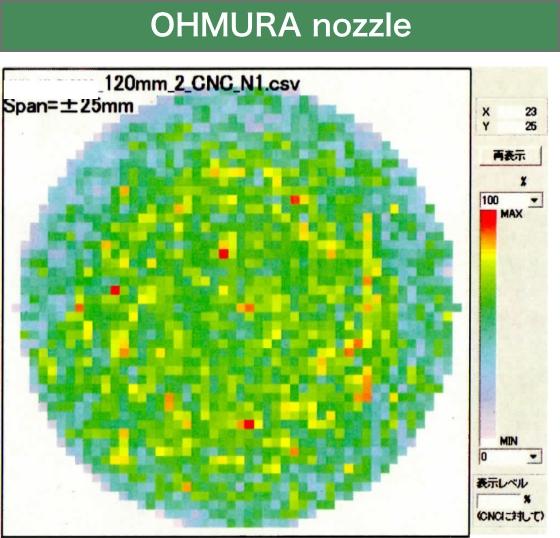

At OHMURA, we carry out in-house evaluation and testing of our custom-made nozzles.

[Test case] Liquid concentration distribution on the cross section 120 mm below the spray hole

Measurement with CT-LDSA (computed tomography)

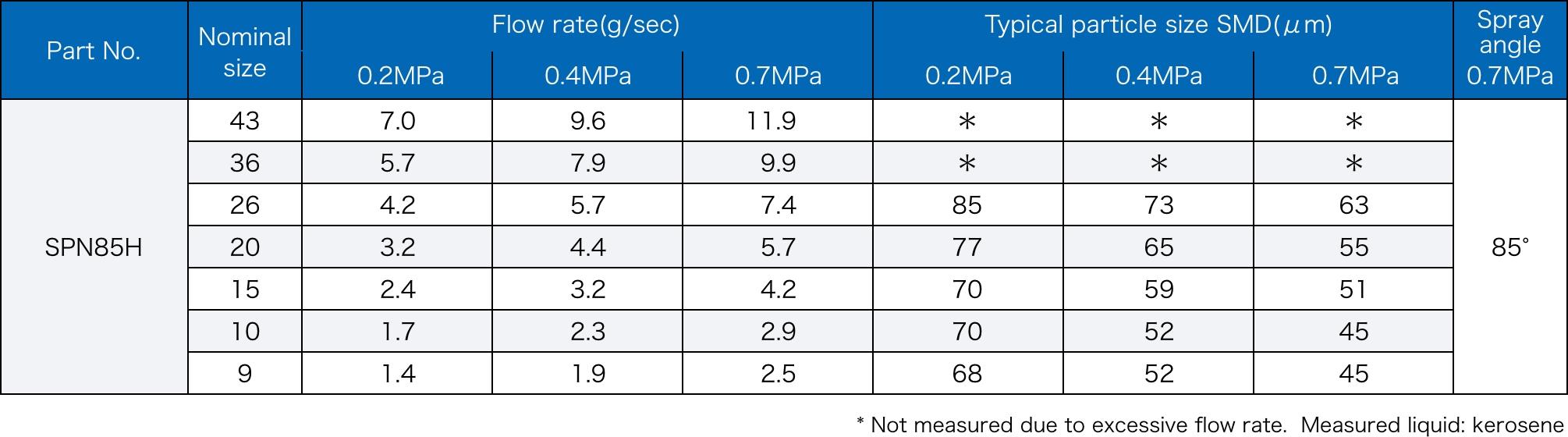

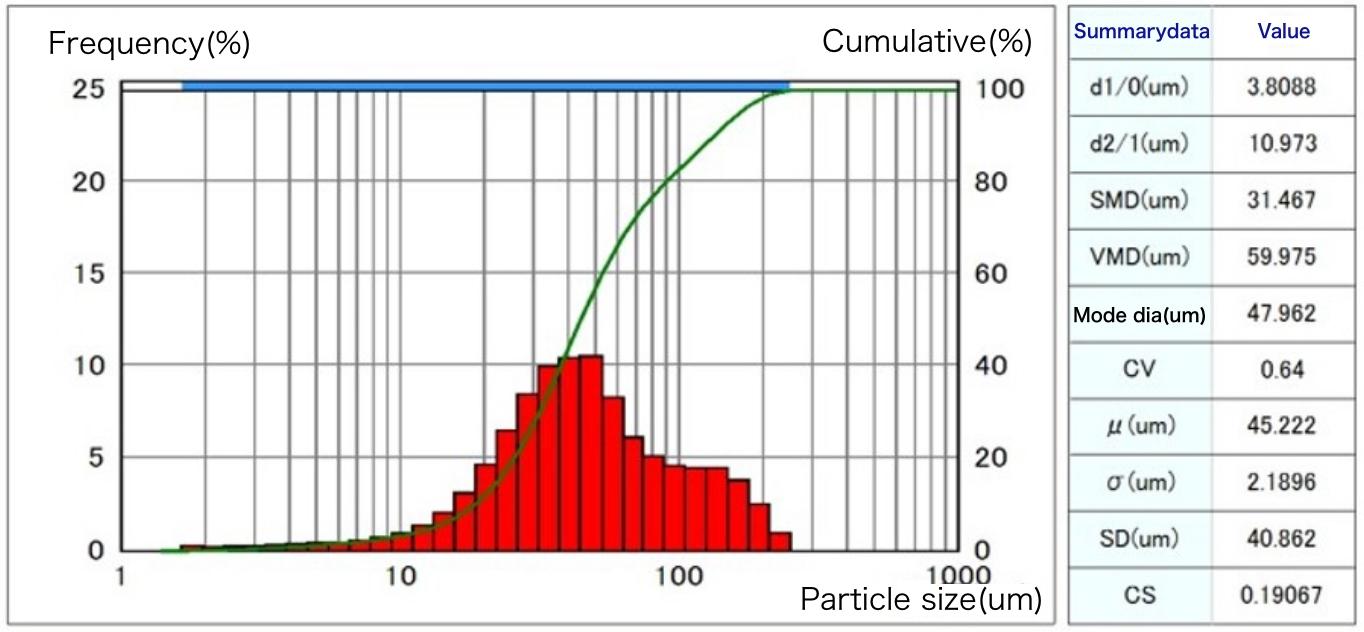

[Particle size distribution measurement results]

■Typical atomized particle size measuring equipment

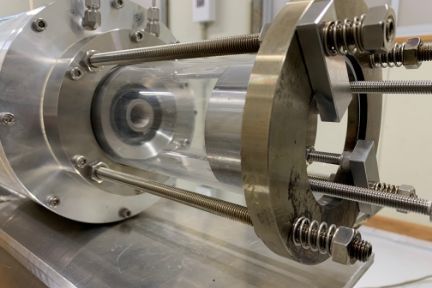

Patternator test equipment

Patternator test equipment Atomized particle size measuring equipment

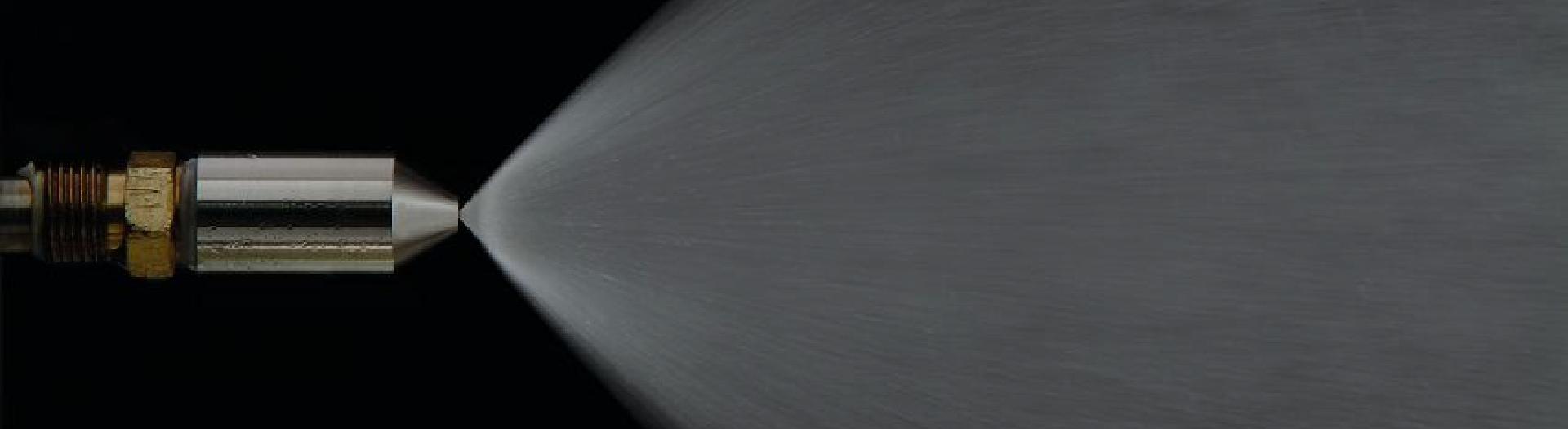

Atomized particle size measuring equipment Atomized particle size measuring equipment (atomized state)

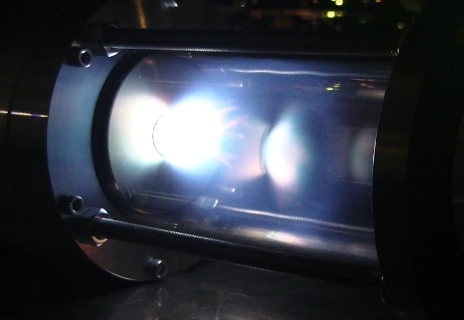

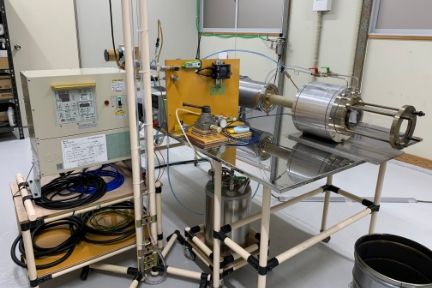

Atomized particle size measuring equipment (atomized state)■Typical combustion test equipment

Chamber, silica tube

Chamber, silica tube Entire combustion test equipment

Entire combustion test equipment Air blower

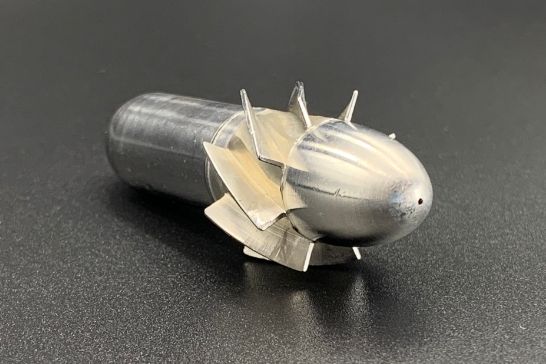

Air blowerManufactured Part Examples

OHMURA can offer a consistent response to customer needs from the preliminary design stage to evaluation and testing.